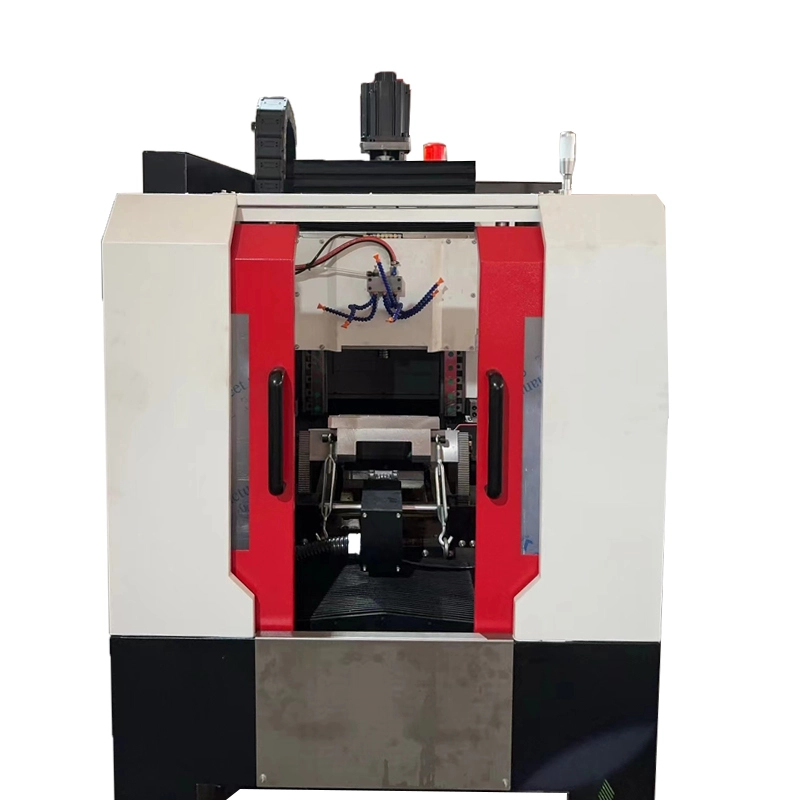

Intelligent Heat Sink Fin Skiving Machine

This intelligent CNC skiving machine is developed by our factory. The heat sink fin skiving machine can produce thinner, higher density and more efficient skived fin heat sink. Lori heat sink fin skiving machine is versatile, taking into account the rigidity of the skiving and the dynamic performance of the skiving, suitable for mass production of large and small aluminum skived fin heat sink or copper skived fin heat sink. And it is driven by high speed servo motor to improve skiving speed and saving product processing time.

Advantages of CNC Skiving Machine

- The vertical skiving machine is good rigidity, high precision skiving fin, wide application range, easy to operate;

- Parametric variable program, users only need to enter the tool parameters and related process parameters to achieve processing, no programming.

- The heat sink fin skiving machine high efficiency, unique numerical control technology, to ensure that the machine high-speed operation, stable and no impact.

- CNC skiving fin heat sink machine and skiving grinding tool holder, so that the skiving process change is simple and convenient, the cross tool holder has a quick return handle and an adjustable limit rod, can be quickly and accurately adjusted to the next cutting depth.

- Intelligent, data input, human-computer interaction interface, through simple data input can achieve automatic control processing.

Related Parameters

| Model No. | LRL-6030 | Skiving fin minimum step | 1 to 1(Fin Thickness vs. Step ) |

| X axis travel | 600 (mm) | Machine total power | 10 KW (Not include vacuum pump) |

| Z axis travel(work surface) | 180 (mm) | Control System | Taiwan LNC |

| Working desk size | 600*400 (mm) | 300mm skiving cutter | 2 cutters |

| Sucker size | 665*300 (mm) | Knife sharpener | One |

| X axis moving speed | 10 meter/min | X/Z axis screw | Taiwan HIWIN |

| Z axis moving speed | 10 meter/min | X/Z axis rai | Taiwan HIWIN |

| Skiving fin maximum length | Copper 600mm, Aluminum 600m | X/Z axis servo motor | ZONCN/VEICHI |

| Skiving fin maximum width | Copper 150mm, Aluminum 150mm | Precision | Repeat positioning accuracy is less than 0.02mm |

| Skiving fin maximum thickness | Copper 0.5 mm, Aluminum 0.8 mm | Bearing | FAG |

| Skiving fin minimum thickness | 0.05 mm | Dimensions | L2200 * W1700 * H2050 |

| Skiving fin maximum step | 10mm | Overall weight (approx) | 2.5 tons |

| Skiving fin maximum height | Copper 30, Aluminum 60 mm |

sample pictures

This special CNC skiving machine skives the fins out of a single piece of material (copper or aluminum) to form a one-piece heat sink with the fins and base attached.